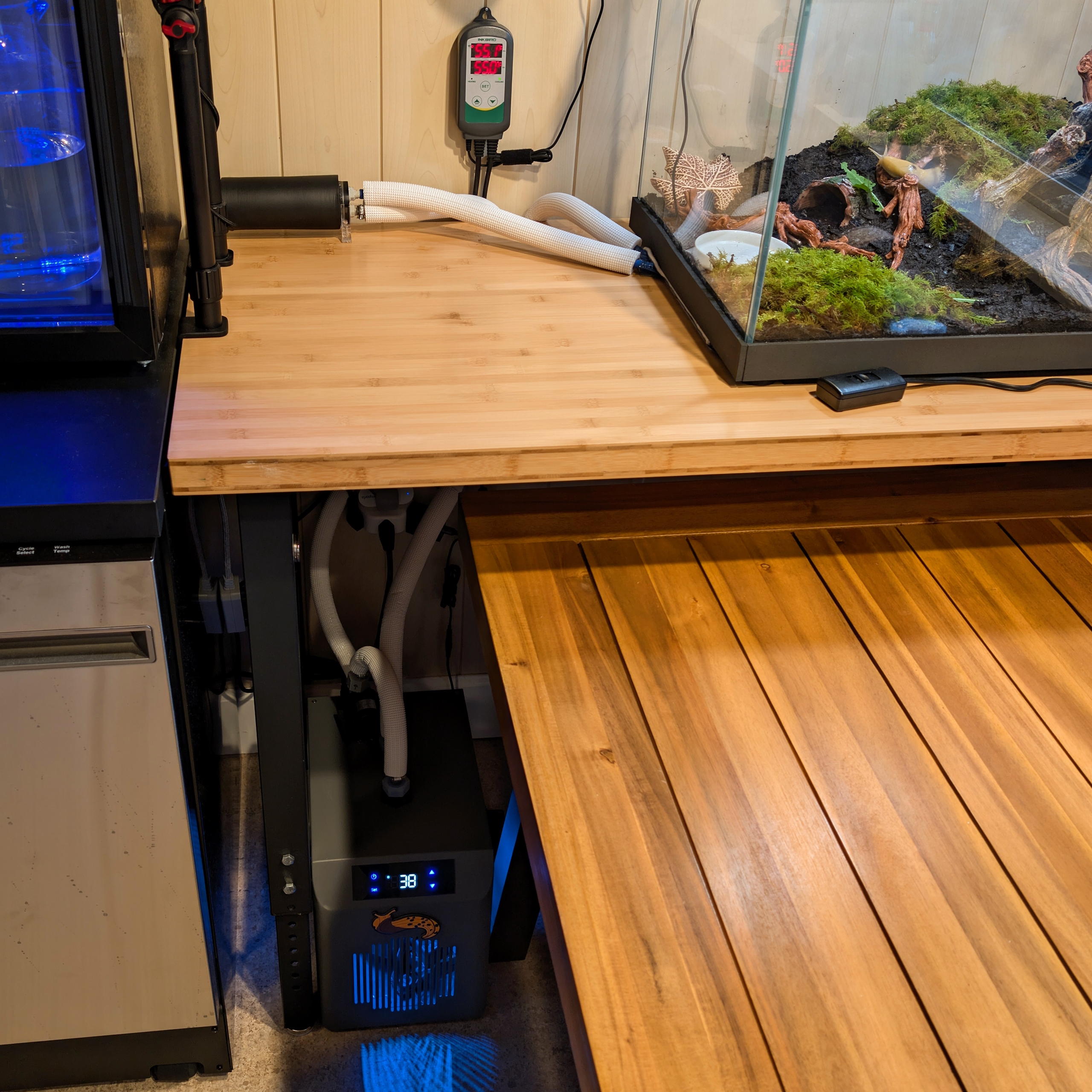

Concept

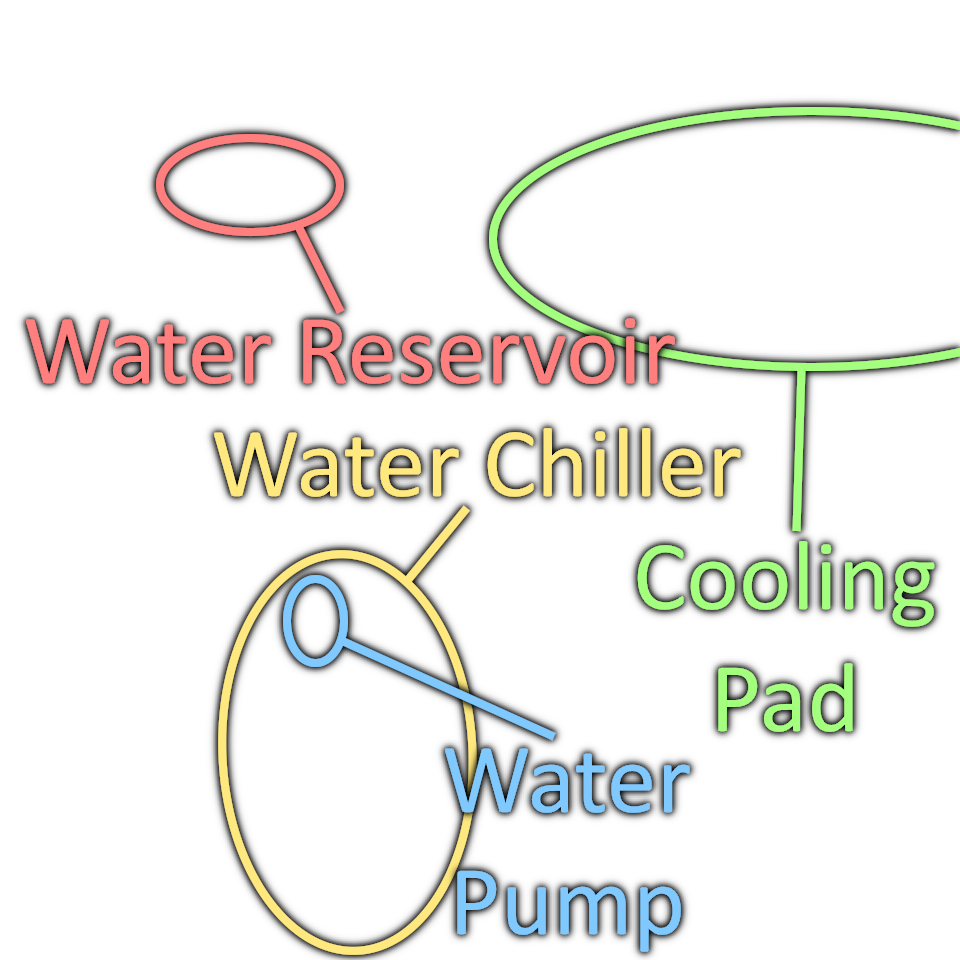

The use of an aquarium chiller to cool water pumped through a cold-therapy pad, which can be placed beneath an enclosure. This enables a great degree of cooling without directly impacting humidity, and creates a vertical thermal gradient that allows residents to pick and choose their ideal temperature.

I personally employ this solution for Banana Slugs, which prefer temperatures of ~55°F (13°C).

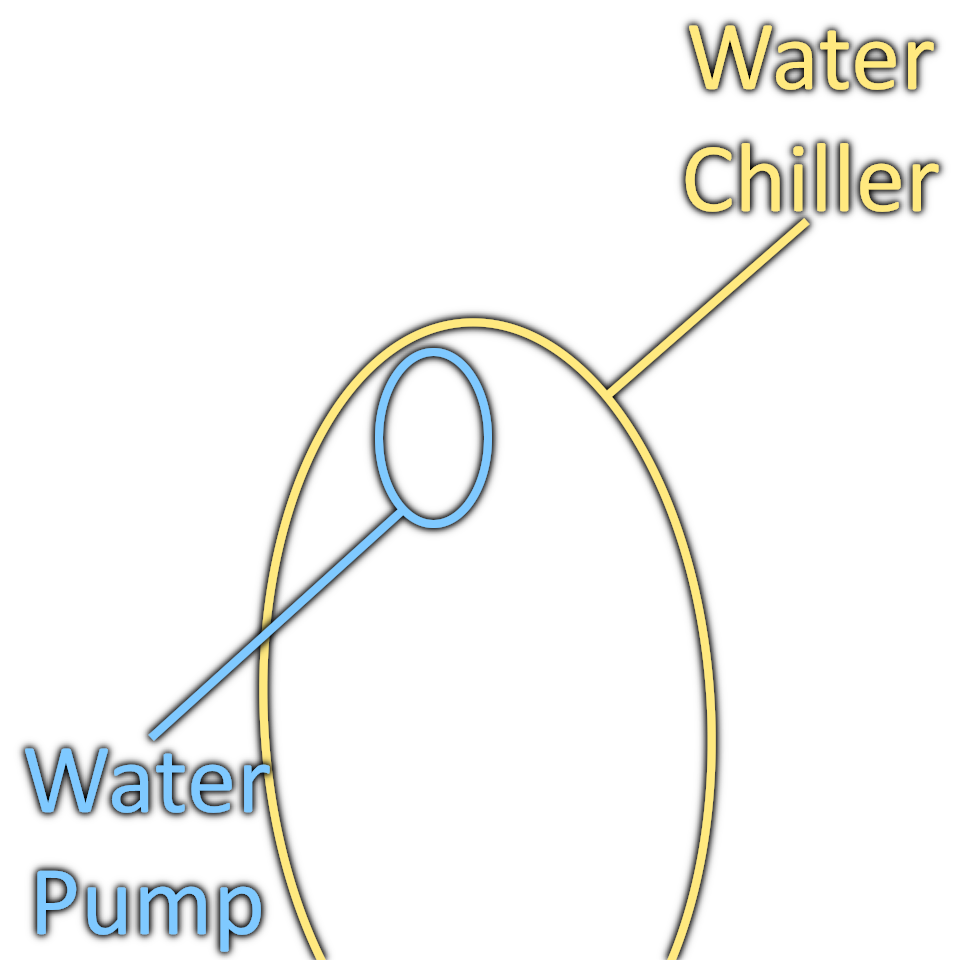

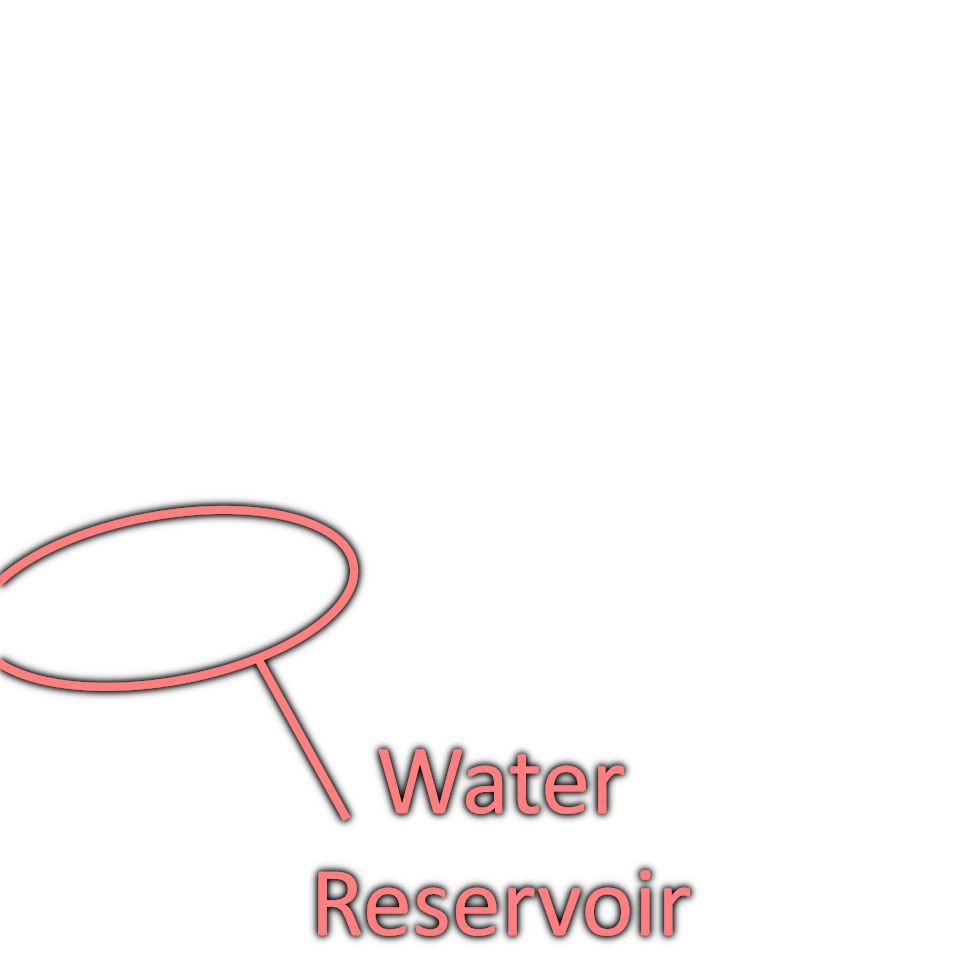

Tap pictures for identification.

Parts List

Prices Last Updated: September 22nd, 2025

Minimum Parts

| Water Chiller | 269.99 | |

|---|---|---|

| Water Pump | 19.54 | Pump failed after ~1yr of operation — consider keeping a spare. |

| 12v Power Supply | 6.99 | To power water pump. |

| Cooling Pad | 57.99 | Subtract 4" (10cm) from each of your enclosure's footprint dimensions to determine the largest cooling pad that may be used. This ensures enough space for the risers to support the enclosure's weight. |

| Risers | 13.75 | To create gap for cooling pad beneath enclosure. |

| Water Reservoir | 20.59 | Collects air trapped in cooling loop. |

| Reservoir Cap | 6.59 | To seal reservoir's fill-port. |

| Reservoir Insulation | 13.40 | To improve thermal performance and limit condensation. |

| Wax Lubricant | 10.99 | Enables installation of reservoir's insulation. |

| G1/2 to 8mm Barb | 9.29 | Water pump fittings. |

| G1/4 to 5/16 Barb | 7.79 | Reservoir fittings. |

| G3/4 to 5/16 Barb | 8.49 | Replaces water chiller's fittings for use with 5/16 tubing. |

| 5/16 to 5/16 Barb | 6.99 | To extend cooling pad tubing. |

| 5/16 Tubing | 5.99 | To interconnect loop's elements. |

| Tubing Insulation | 15.19 | To improve thermal performance and limit condensation. |

| Hose Clamps | 5.79 | To secure tubing to barb fittings. |

| Thermal Probe | 5.88 | To monitor substrate temperature. |

| 1G Distilled Water | 2.00 | Coolant. |

| Total | ||

Optional Upgrades

| Silicone Mat | 9.99 | To protect surface beneath cooling pad from condensation if coolant drops below dew point. |

|---|---|---|

| Silicone Tray | 14.99 | To protect surface beneath water reservoir from condensation if coolant drops below dew point. |

| Enclosure Insulation | 12.99 | To improve thermal performance. Install to any unobstructed surfaces on outside of the enclosure, at and below substrate height. |

| Damper Pads | 12.83 | Affixing to the base of water pump reduces vibration noise. |

| Notification Probe | 31.70 | Alternative substrate probe for alterting to out-of-bound thermals. |

| Substrate Thermostat | 35.00 | Replaces the substrate probe, enabling thermal stability in highly variable ambients by controlling power to the water pump and chiller. Set water thermostat to 34°F (1°C). Substrate varied by 3°F (1.5°C) with a 1°F (0.5°C) substrate thermostat differential. |

| Time-Delay Outlet | 31.99 | Protects water chiller from damage if utility power is briefly lost. Install between outlet and chiller, or between outlet and substrate thermostat if one's used. |

Assembly

It's only about half as hard as it looks.

Required Tools

| #0 Phillips Screwdriver | To fasten pump wires to power supply terminals. |

|---|---|

| Slot Driver | To fasten hose clamps and reservoir cap. |

| 14mm or Adjustable Wrench | To fasten G1/4 fittings. |

| Measuring Tape | To measure for cuts. |

| Scissors | To cut tubing and insulation. |

| Heat Gun or Hair Dryer | To make cooling pad's tube malleable enough to connect fittings. |

| Small Funnel | To fill reservoir with coolant. |

| Paper Towels | To clean excess wax and soak up any leaked water. |

Instructions

Prep Water Chiller

- Chillers must be kept upright for at least 24 hours before any operation, which ensures that their compressor's oil has settled to a safe level. Failure to allow this time will typically result in compressor damage.

- Locate two G3/4 to 5/16 barb fittings, and place one of the chiller's included o-rings within each.

- Fasten these two prepped fittings to the top of the chiller.

Prep Cooling Pad

- With scrissors, cut the fitting off the end of the pad's tubing and discard the included insulation.

- Cut the pad's remaining tubing to 1" (25mm) lengths and discard the removed lengths.

- Install a 5/16 to 5/16 barb fitting on each of the pad's tubes. Fitment will be very tight, so the tube ends may require a heat gun or hair dryer to make them malleable enough, but be careful to avoid melting anything.

Prep Water Reservoir

- Identify the end with two holes and affix a G1/4 to 5/16 barb fitting to each. Threads are tight so double-check that the gaskets squash upon fastening.

- Affix the reservoir cap to the end with only one hole.

- Ensure that the black end pieces are fully-threaded to the acrylic glass, as they may have loosened during shipping.

Prep Water Pump

- Affix a G1/2 to 8mm barb fitting and their included o-ring to each of the pump's ports.

- Find the exposed copper strands at the end of the pump's wires and cut them to ~4mm lengths.

- Twist each wire's strands together with your fingers until they maintain a single form. Do not twist both sets of strands together into one form — there must still be two independent conductors.

- Locate the 12v power supply's green and black barrel adaptor with screw terminals, and carefully affix the pump's wires, with the red wire corresponding to the positive (+) terminal and black to negative (-).

- Ensure that a gentle tug doesn't dislodge the pump's wires, and that each wire's jacket ends just before the copper is pinched by their respective terminal.

- Connect the power supply's barrel connector to the barrel adaptor.

Stage Components

- Place the water chiller, cooling pad, water reservoir, and water pump in your planned locations. The reservoir in particular must be oriented horizontally and be at the loop's highest point, as its role is to collect trapped air while the water cycles.

- Measure for four tubing lengths — one between pad and reservoir, pad and chiller, chiller and pump, as well as the reservoir and pump. Lengths should not be taut.

Prep Tubing

- Cut tubing in accordance with the previous measurements.

- Sleeve the tubing insulation such that all but 1" (25mm) at each end of the tubes are fully covered. Fitment is very tight, so avoid sleeving more than 18" (45cm) of insulation at a time.

Install Tubing

- Use the now insulated tubing to connect the water pump's side fitting to one on the water chiller, and the chiller's remaining fitting to one on the pad. Connect the pad's remaining fitting to the reservoir fitting featuring an internal tube (visible through the acrylic), and connect the reservoir's second fitting to the pump's remaining fitting.

- Ensure that the reservoir can rotate such that the port connected to the pad is oriented above the one leading to the pump.

- Affix hose clamps to the tubing over their fitting's barbs.

- Take a break — this is about to get spicier.

Add Coolant

- Reassess fittings to confirm that they're sufficiently secure.

- Ensure that the water pump's power supply is within reach and can be easily connected to an outlet.

- Remove reservoir cap and orient the reservoir such that its open port faces up and the tubes are downward, again ensuring that the reservoir is the loop's highest point.

- Loosely insert a funnel into the open port and add distilled water until the reservoir is ~80% full.

- While maintaining reservoir orientation, plug the pump's power supply into an outlet.

- Water should drain from the reservoir and there will be strange noises as the pump struggles with air pockets. Keep adding water to the reservoir and maintain a water level of at least 80% (it's okay if it drops below this level for short periods).

- Once the water's flow seems steady and the reservoir maintains at least an 80% water level on its own, ensure that this remains the case for at least 2 consecutive minutes.

- Reaffix the reservoir cap.

- Rest the reservoir on its side while also ensuring that the port leading to the pad is kept oriented above the second tube port, else the reservoir's air may be reingested back into the system.

Add Reservoir Insulation

- Cut the reservoir insulation to a length of 5.5" (14cm).

- Coat the cut insulation's inner diameter with wax lubricant, else the fitment will be too tight.

- Sleeve insulation over the reservoir until the water is no longer visible.

- Clean up excess lubricant with a paper towel.

- Find the reservoir's plastic feet and affix them to the black end caps.

- Set the reservoir back down while remaining mindful of its proper orientation — the port leading to pad must orient above the port leading to the pump.

Position Cooling Pad

- Set the enclosure in its planned location.

- Place a rubber riser beneath each of the glass' four corners.

- Lift one side of the enclosure and slide only the cooling mat (not the tubes) beneath it.

- Set the enclosure back down and ensure that each of the risers is taking some of the enclosure's weight. The pad should be compressed against the glass but not taking all of the enclosure's weight.

Populate Enclosure

- Add substrate.

- Install thermometer with its probe above the cooling pad on the substrate's surface.

Configure Water Chiller

- Power on the chiller and set its thermostat differential to 4°F (2°C).

- Set a water temperature based on the performance deltas in the following section.

- Take a break for ~6hrs to allow the enclosure's thermals to settle.

Tune System

- Assess fittings for leaks and tighten anything suspect. Some condensation is normal if coolant drops below the dew point.

- Begin adjusting the water's temperature to reach the desired substrate temperature, and allow ~2hrs before reassessing these adjustments.

Performance

Based upon the "Minimum Parts" list.

Observation Conditions

| Ambient | 72°F (22°C) |

|---|---|

| Substrate | 1" (25mm) Topsoil |

| Enclosure Material | 5/16" (8mm) Glass |

| Enclosure Footprint | 24x18" (60x45cm) |

Water to Substrate Deltas

| Wet Soil | 7°F (4°C) |

|---|---|

| Dry Soil | 15°F (8°C) |

Power Draw

| Idle | 7W |

|---|---|

| 48°F (9°C) Water | 145W (30% Duty) |

| 38°F (3°C) Water | 145W (100% Duty) |